Stage II. Optimization by modeling and experimentation of plasma treatment processes applied to textile materials in order to obtain multiple functionality of electromagnetic attenuation and fireproofing (EMFiRe)

Objectives

The objectives of this stage aimed an integrated approach by modeling and experimenting in order to reach the effect of electromagnetic attenuation in woven materials, starting from mixed structures in which both the structure of the material with inserted conductive wires, and metal coatings obtained by deposition are considered. We were envisaging as well an optimization of metal thin film deposition conditions by magnetron spraying, and of the treatment processes to obtain flame retardant properties. Systematic studies on compositional, physical-mechanical and functional properties were conducted. A LCA study according to the standard SR EN ISO 14040, covering the production phase of multi-functional textiles was also performed.

The main results attained during Stage 2 - 2019

During the 2nd Stage of the project, the mathematical modeling of the textile structures with inserted conductive threads was performed, in order to establish the level of shielding depending on the properties of the materials used. Two types of conductive yarns with wide use in the textile industry were considered, namely Bekinox type stainless steel yarns (containing a mixture of PES fibers and stainless steel fibers), with lower commercial value, but also with lower shielding properties, and respectively Statex silver yarns (containing 6.6 silver-coated polyamide threads), more expensive but also with better conduction, thus presenting higher EM shielding values.

In order to test a wide variety of textile supports, the industrial partners produced several types of materials, by weaving natural fiber materials (BBC) and synthetic fibers (PES) with and without conductive yarns included, according to an experimental matrix of circumscribed composite central plane type, thus obtaining 5 variants of material densities for each type of fiber used, maintaining a constant distance between the conductive wires.

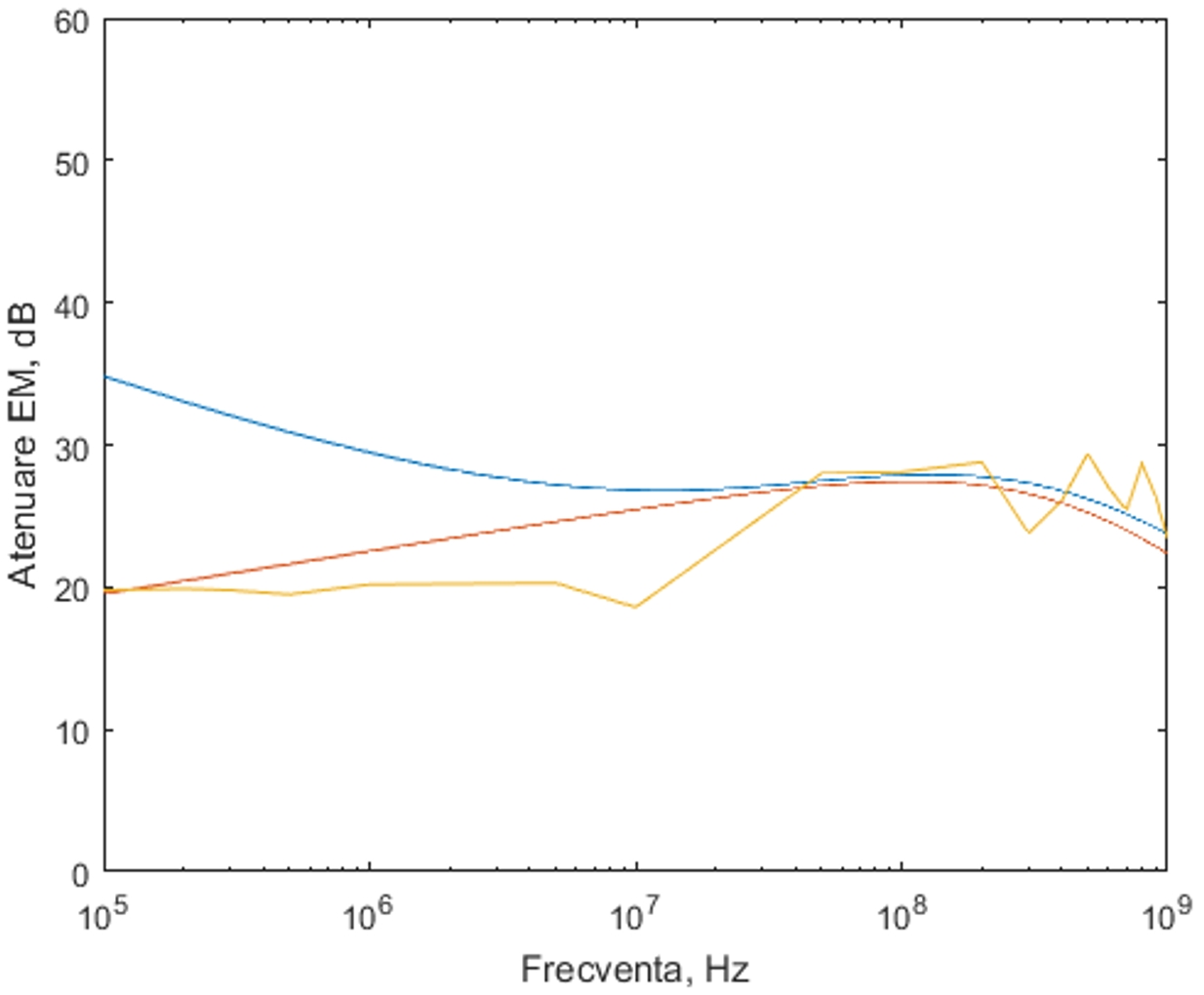

Comparison between the attenuation models for woven material with conductive yarns (red curve),

material covered with copper layer (blue curve)

and the textile material obtained within the project (orange curve)

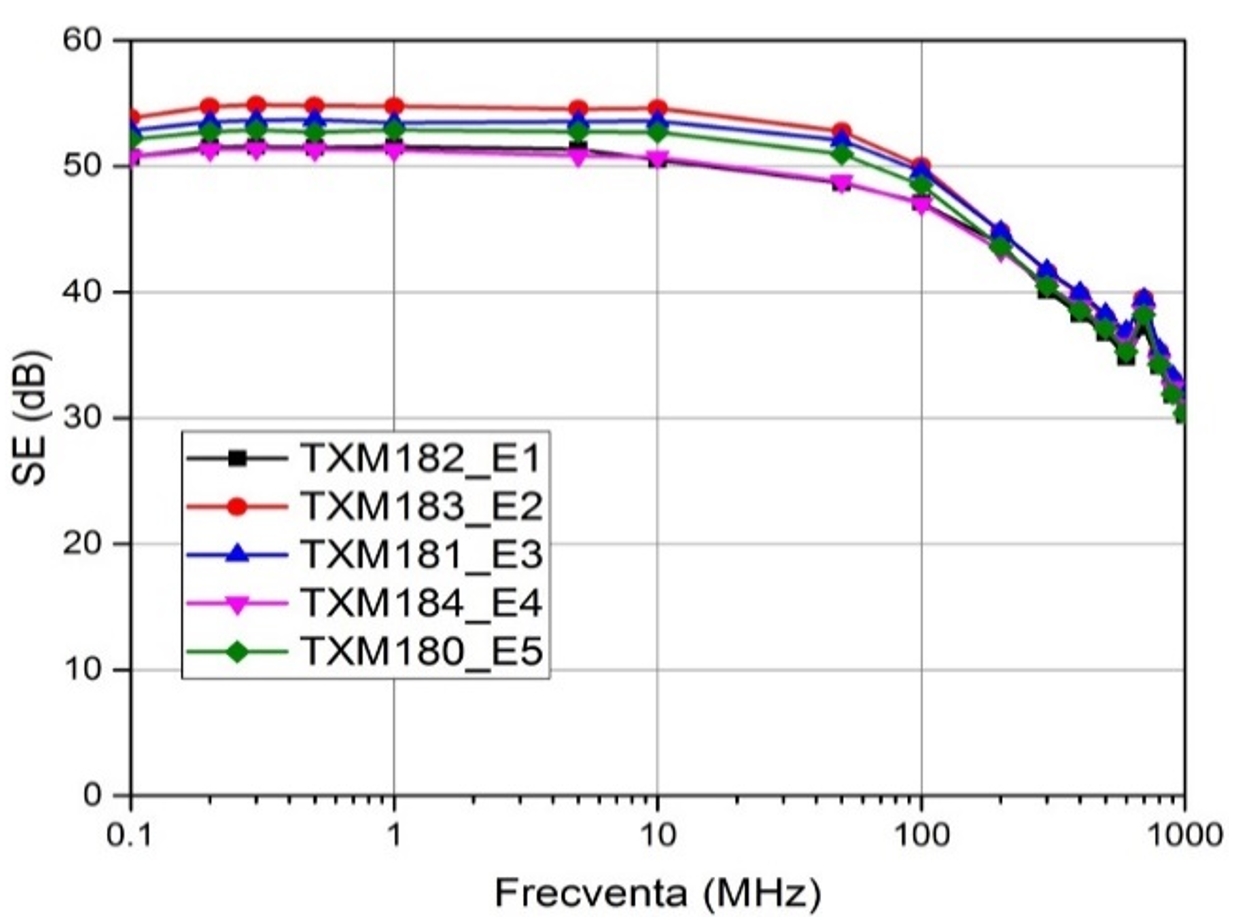

Electromagnetic shielding measurements were performed using two standards, respectively ASTM ES07 - at ICPE - CA and respectively ASTM D4935 -10 at UPB (using a cell built at INFLPR within the project). The results show an increase in attenuation after magnetron spray coating with thin Cu films.

Atenuarea electromagnetică pe probe de bumbac cu fire conductive de Ag inserate

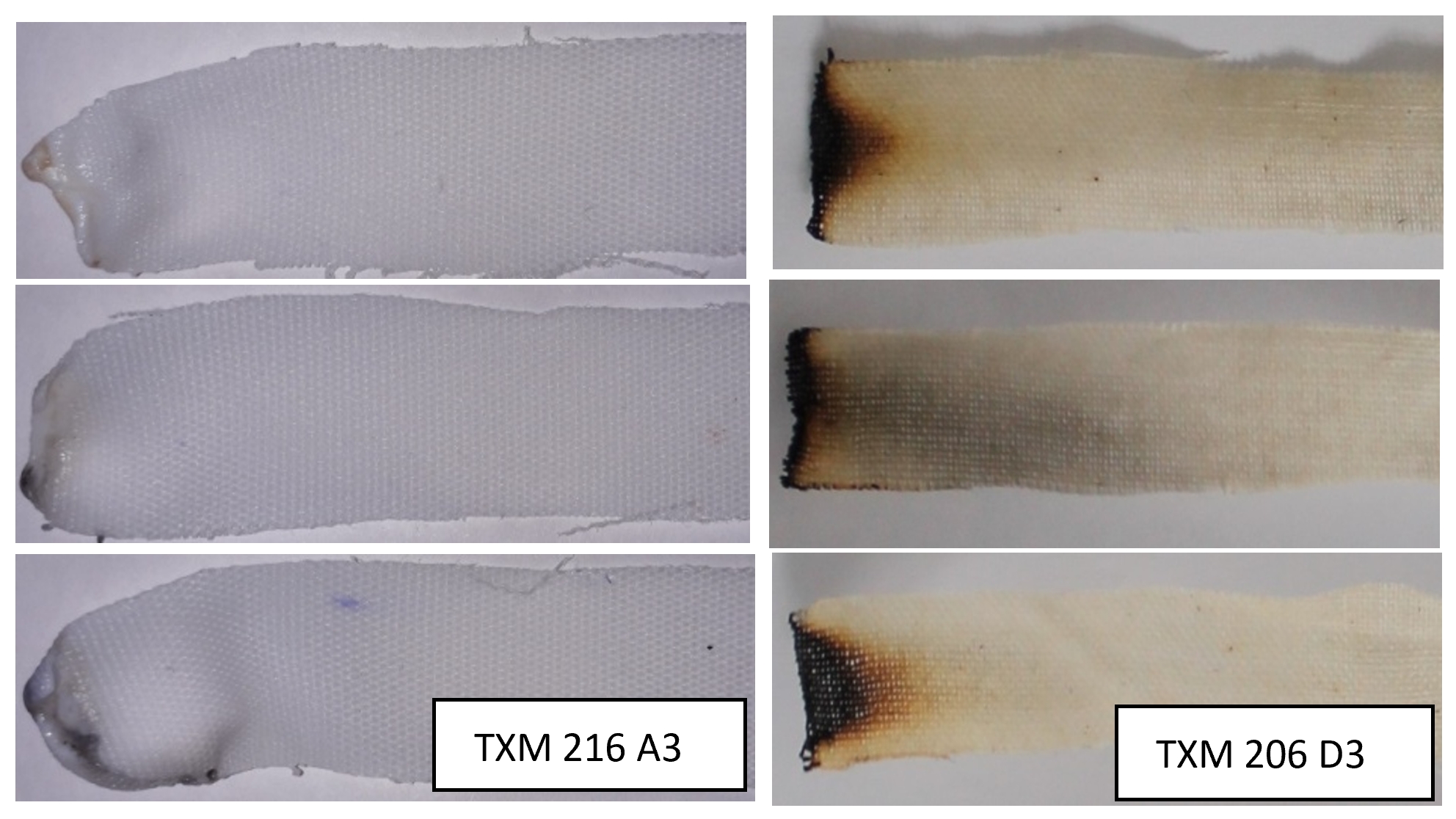

In order to obtain the flame retardant effect of the surfaces under optimized conditions, an atmospheric pressure-induced graft polymerization induction grafting process was used as an alternative method of flame retardant, using Apyrol as the flame retardant. The important flame retardant effect obtained for both types of fabrics is highlighted, respectively neither of the two types of samples allows the flame to propagate after the fire source has been removed, extremely important from the point of view of commercial acceptance for the intended functionality.

Esantioane de PES (stanga) si BBC(dreapta) tratate în plasmă pentru ignifugare și testate la foc

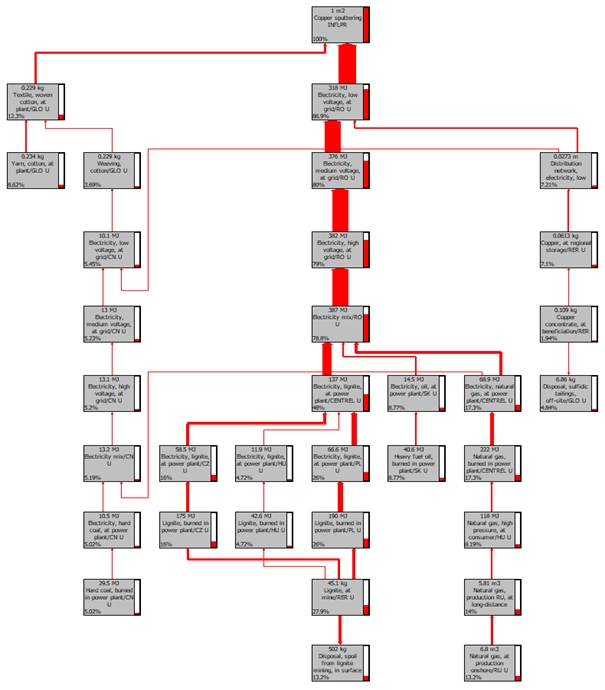

In Stage II of the project, a cradle-to-gate LCA study was performed for textile electromagnetic screen materials, a study based on the results obtained in the first stage of the project. These studies started from the Life Cycle Inventory in which the processes of obtaining textile screens by weaving and covering according to the EcoInvent 3.0 database were taken into account, as well as those provided from actiual consumes from Majutex SRL for weaving and experimental data from INFLPR regarding coating with thin metal layers by magnetron sputtering. Based on them, an environmental impact quantification was performed according to the ISO 14040 standard for a 1 sq m textile screen with an attenuation of 5.2 dB. The main objective of this approach is to collect the input and output data in the system and to calculate on the basis of these data the impact on the environment, using software programs. To illustrate the impact, the EcoIndicator99 method was used, which refers to a number of 11 impact categories, namely: carcinogens, organic and inorganic respirators, climate change, radiation, ozone layer, ecotoxicity, acidification / eutrophication, land use, minerals and fossil fuels.

Process diagrams were used for the input / output data in the system according to LCI (Life Cycle Inventory), which shows the input flows in the system for all component processes of the technological chain. The figure below illustrates the diagram related to the production process of plasma coated screens by magnetron sputtering. The results obtained indicate a significant impact when using laboratory equipment for deposition, due to the small surface area covered and the small deposition rate. In the next stage, a similar study will be performed with the optimized deposition system as input data, with a rate of 100 nm / min.

The dissemination activities related to the second stage of the project are presented below, and highlight the involvement of the entire consortium to obtain significant results in the project, as well as the importance given to transmitting information to the business environment, for a possible implementation of systems developed in project within some Romanian profile companies, and not only.

List of ISI and BDI papers

1. Research regarding the cover factor of magnetron sputtering plasma coated fabrics - Authors: SURDU Lilioara; RĂDULESCU Ion Răzvan; VISILEANU Emilia; STANCU Cristian; ARDELEANU Alina; SANDULACHE Irina; MITRAN Cornelia; MITU Bogdana - Industria Textila ISSN 1222–5347 2/2019 (ISI)

2. Research regarding achievement electromagnetic shields based on textile substrates – Buletin AGIR nr. 3 / 2019/ Authors: Lilioara SURDU; Emilia Visileanu; Ioan Razvan Rădulescu; Bogdana Mitu

Proceedings in extenso of international conferences

1) Electromagnetic shielding achieved by plasma coated fabrics - Authors Radulescu Ion Razvan, Surdu Lilioara, Visileanu Emilia, Mitu Bogdana, Ardeleanu Alina, Veronica Satulu, Badic Mihai, Cristian Morari - Proceedings of the 19th World Textile Conference - Autex 2019; Open Journal Systems

2) Electromagnetic Shielding out of plasma coated woven fabrics - Authors: Lilioara SURDU; Ioan Razvan Rădulescu; Bogdana Mitu– Proceedings of TexTeh, ISSN 2068-9101, Vol. 9

3) Fabrics for Buildtech electromagnetic shields based on plasma magnetron sputtering - Authors: Lilioara SURDU, Alina ARDELEANU, Emilia VISILEANU, Ion Răzvan RĂDULESCU, Mihai BADIC, Cristian MORARI, Bogdana MITU Proceedings of TexTeh, ISSN 2068-9101, Vol. 9

4) Preparation of superhydrophobic cotton fabrics based on fluorocarbon compounds by plasma methods, autori V. Satulu, B. Mitu, I.R. Radulescu, R.M. Aileni and G. Dinescu, Proceedings of the 24th International Symposium on Plasma Chemistry (ISPC 24), ID 512

List of participations at international conferences

1) Electromagnetic shielding achieved by plasma coated fabrics - Authors Radulescu Ion Razvan, Surdu Lilioara, Visileanu Emilia, Mitu Bogdana, Ardeleanu Alina, Veronica Satulu, Badic Mihai, Cristian Morari - AUTEX2019 – 19th World Textile Conference on Textiles at the Crossroads, 11-15 June 2019, Ghent, Belgium

2) Electromagnetic Shielding out of plasma coated woven fabrics - Authors: Lilioara SURDU; Ioan Razvan Rădulescu; Bogdana Mitu– Poster/ TexTeh IX, 24-25 October 2019, Bucharest, Romania

3) Fabrics for Buildtech electromagnetic shields based on plasma magnetron sputtering - Authors: Lilioara SURDU, Alina ARDELEANU, Emilia VISILEANU, Ion Răzvan RĂDULESCU, Mihai BADIC, Cristian MORARI, Bogdana MITU – oral presentation TexTeh IX, 24-25 October 2019, Bucharest, Romania

4) Preparation of superhydrophobic cotton fabrics based on fluorocarbon compounds by plasma methods, autori V. Satulu, B. Mitu, I.R. Radulescu, R.M. Aileni and G. Dinescu, poster ID 512, 24th International Symposium on Plasma Chemistry (ISPC 24), Sunday – Friday, 9 June – 14 June 2019. Naples

5) Fabrics with electromagnetic shielding properties achieved by magnetron sputtering deposition - A.A. Ardeleanu, C. Stancu, L. Surdu, E. Visileanu, I-R. Radulescu, M. Badic, C. Morari, B. Mitu- XVIIIth International Conference on Plasma Physics and Application 20th–22nd June 2019, Iasi, Romania, poster P3-18

6) LDH/POSS nanoadditives for improved fire resistance in cotton textiles, Giuseppe ROMBOLA, Valentina GIANOTTI, Marco MILANESIO, Luca PALIN, Eleonora Andrea BASSO, Michele SETARO, Lilioara SURDU, Bogdana MITU- oral presentation during Industrial Workshop on Recent Advances in Technical textiles, - TexTehIX, 25th October, 2019

7) Research regarding electromagnetic shielding achieved by the fabrics support – Authors: Lilioara SURDU, Raluca Maria Aileni, Razvan Ion Radulescu, Laura Chiriac / oral presentation at 7th Edition of the International Conference on Intelligent Textiles & Mass Customisation - ITMC 2019 / Smart Textiles Salon Vol.7 – STS 2019- November 13-15, 2019, Marrakesh, Morocco

8) Fabrics with electromagnetic shielding properties achieved by magnetron sputtering deposition;

Authors: Lilioara SURDU, Raluca Maria Aileni, Razvan Ion Radulescu, Laura Chiriac, Bogdana Mitu / Technical Textiles - Present and Future Symposion; Iasi; Romania, November 15, 2019, poster

9) Research regarding achievement electromagnetic shields based on textile substrates – Authors: Lilioara SURDU; Ioan Razvan Rădulescu; Bogdana Mitu - oral presentation at Simpozion AGIR – Progresul Tehnologic Rezultat al Cercetarii Ediția a XIV –a / 9 mai 2019

Books

Editura Certex/2019 - EVALUAREA CARACTERISTICILOR MATERIALELOR TEXTILE AVANSATE – Autors: Lilioara SURDU; Emilia VISILEANU; Ioan Razvan RĂDULESCU

Participation to exhibitions in the filed of the project

1. Meetings between the representatives of MAJUTEX SA and representatives of CHT Switzerland AG, implicitly with the laboratory teams - at the headquarters of CHT Switzerland AG in Switzerland

2. Participation in the ITMA Exhibition, 20-26.06.2019, BARCELONA, Spain for documentation on the latest technologies in the textile industry, identification of suppliers of special yarns (stainless steel, silver).

Organization and participation to project meetings

1. Mid-term meeting, organized by Tecnolab in Italy, at Laggo Maggiore, respectively at Unione Industriali del Verbano Cusio Ossola, on May 13, 2019, with the participation of Ms. Enrica Lamartin from the Finpiemonte Financing Agency.

2. Project meeting organized by INFLPR on 25.10. 2019, at the Capital Plaza Hotel in Bucharest, in conjunction with the TexTeh IX International Conference

Organizing an industrial workshop dedicated to the latest advances in the field of technical textiles

On the 25th of October. 2019 took place the Workshop Recent Advances in Technical Textiles at the Capital Plaza Hotel in Bucharest, with guests from Minho University in Portugal, the AEI TExTILS cluster in Spain, which is currently coordinating a COST action dedicated to smart textiles, from the company Centexbel from Belgium, as well as researchers from Italy, from Environment Park and the University of Eastern Piedmont. More than 50 people participated, including a significant number of companies that are part of the Romanian Textile Concept cluster.

Manufacturing textiles with electromagnetic shielding and fire retardant properties by plasma based methods

Manufacturing textiles with electromagnetic shielding and fire retardant properties by plasma based methods